TASK _ DEVELOP A SUSTAINABLE PACKAGING

CONCEPT FOR GROCERY STORE APPLICATIONS

︎︎︎

WHY ?

WE NEED TO CHANGE THE USE OF ONE WAY

PACKAGING AND OUR PURCHASING BEHAVIOUR ...

Why always 500g pasta? For logistical reasons, food is predominantly offered in unit sizes. The quantities required by each customer vary greatly. Is individual packaging necessary? In the food supply chain, it is only the last step from the retailer to the customer or consumer that requires division by individual packaging.

Do we shop differently today? A new trend in shopping behavior can be observed especially in cities. The big weekly shop is giving way to smaller and more frequent errands.

And why is the proven bottle deposit system which is already being used successfully in some countries not being transferred to other areas of the food industry? REPAQ should be an attractive, universal, and sustainable option for exactly this purpose.

And why is the proven bottle deposit system which is already being used successfully in some countries not being transferred to other areas of the food industry? REPAQ should be an attractive, universal, and sustainable option for exactly this purpose.

HOW ?

DEVELOPING A NEW ARCHETYPE FOR FOOD SHOPPING...

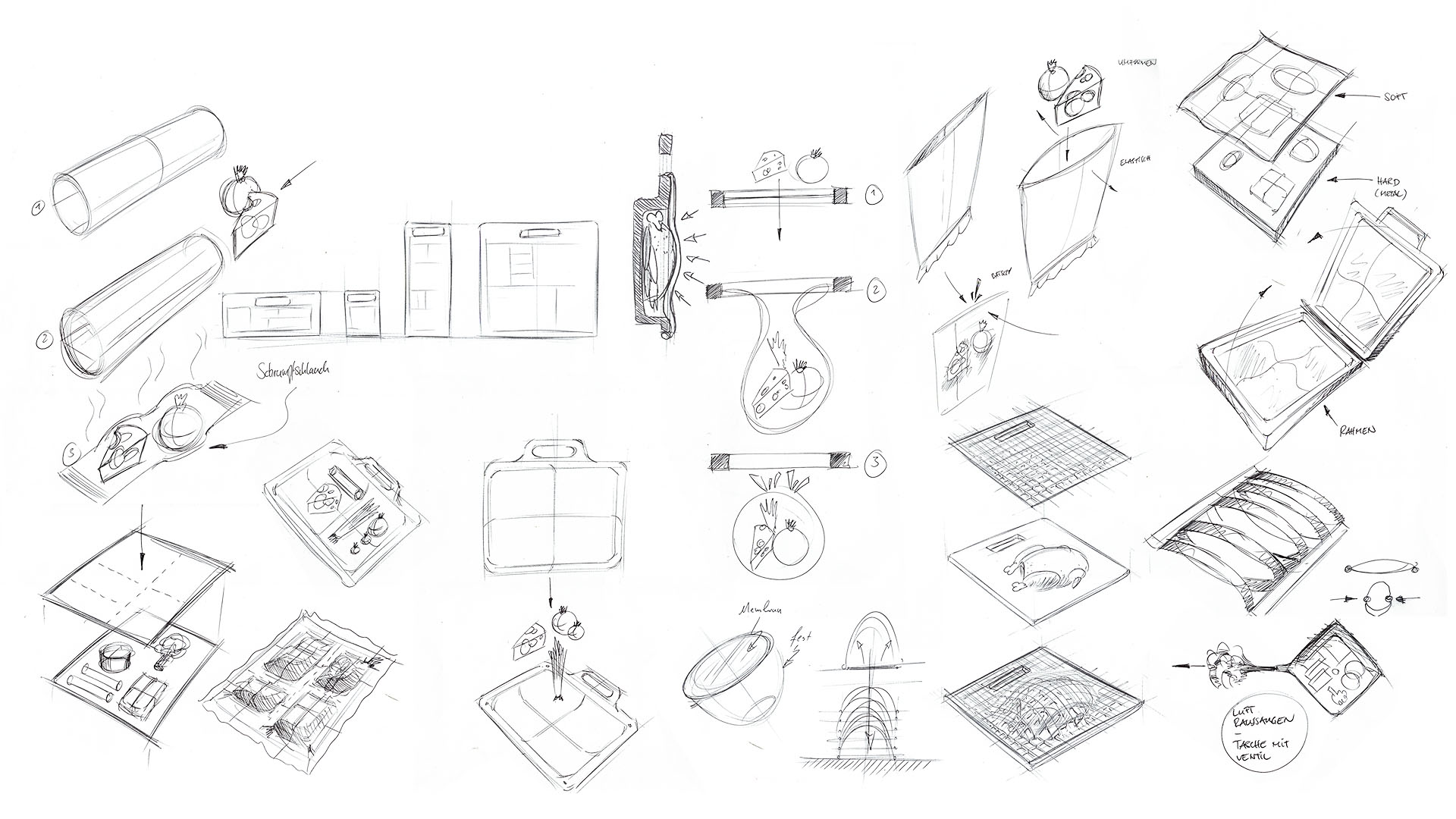

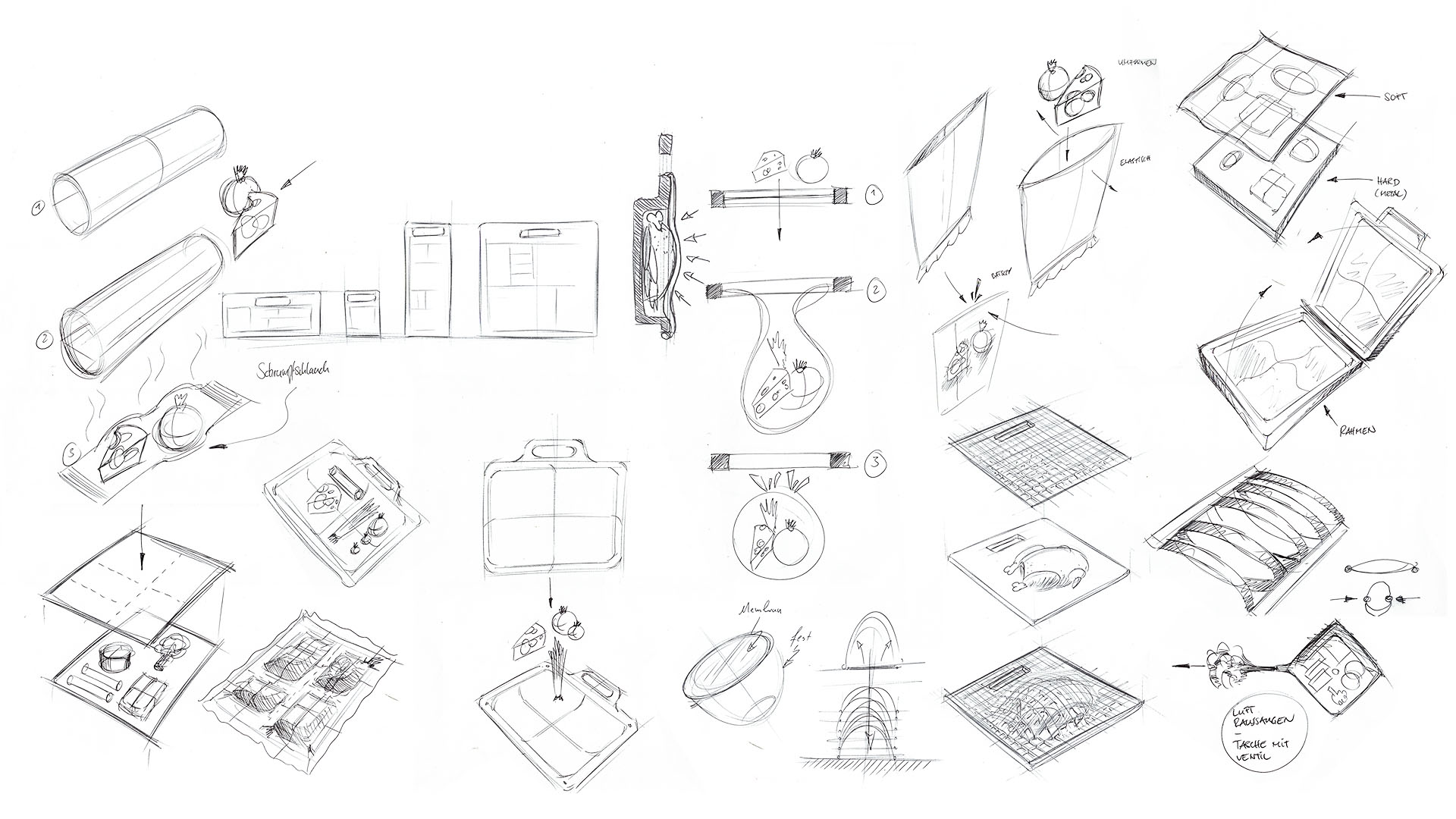

The product had to be as simple as possible for cleaning, production, and recycling, but also meet the requirements of safe packaging. Keywords for the development process included: Sustainability by replacing disposable packaging so only one product instead of many small and individual units. Individuality by adjusting quantities to avoid superfluous packaging and food waste. Universality through different supply scenarios like pickup services, classic shopping, or delivery.

Vacuuming has many uses in food storage and cooking.

A durable, high-quality, and reusable packaging concept could also use this method to seal itself, fix different purchases and keep food fresh. The fixed condition of open and closed also allows a systematic return cycle.

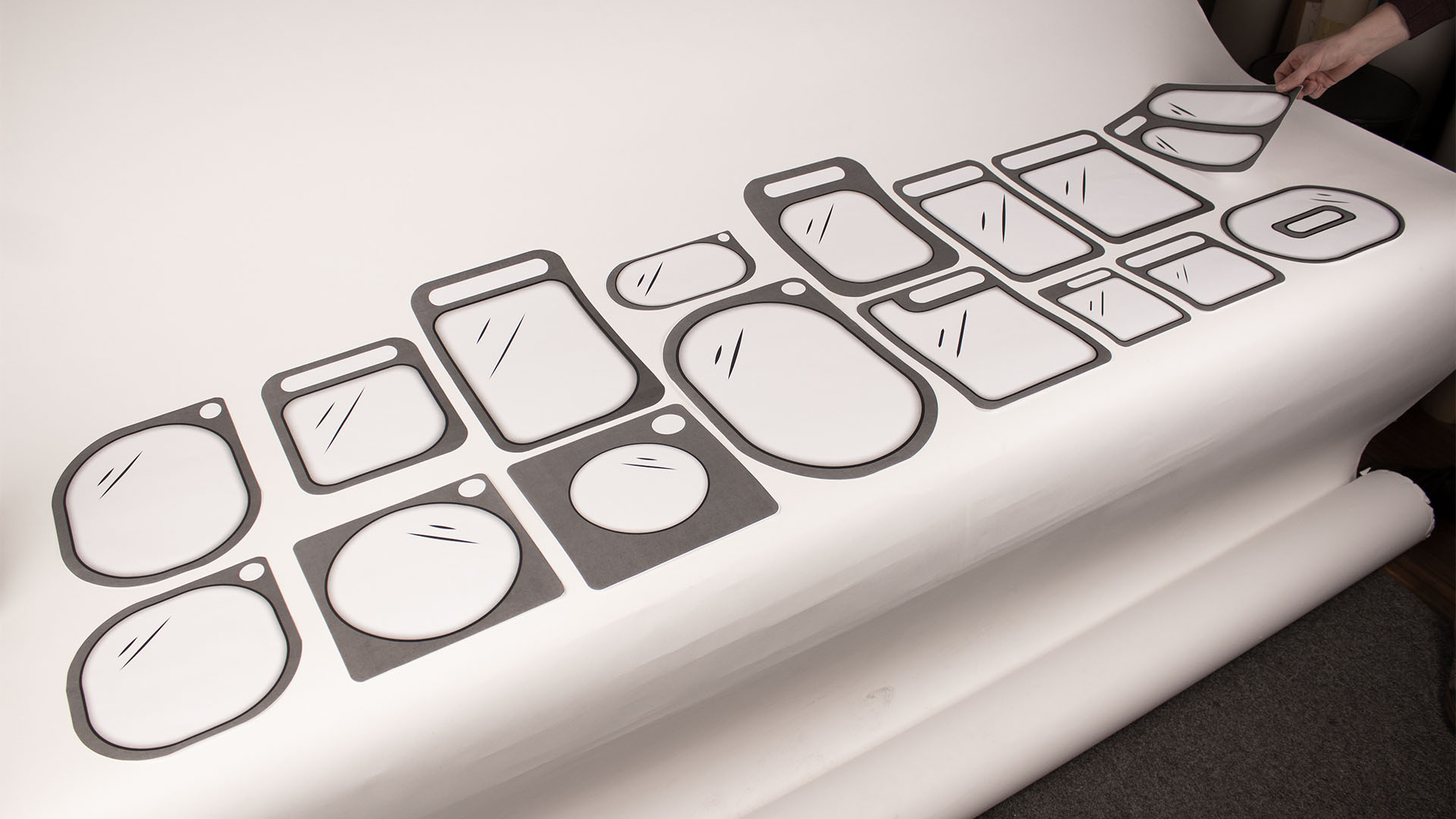

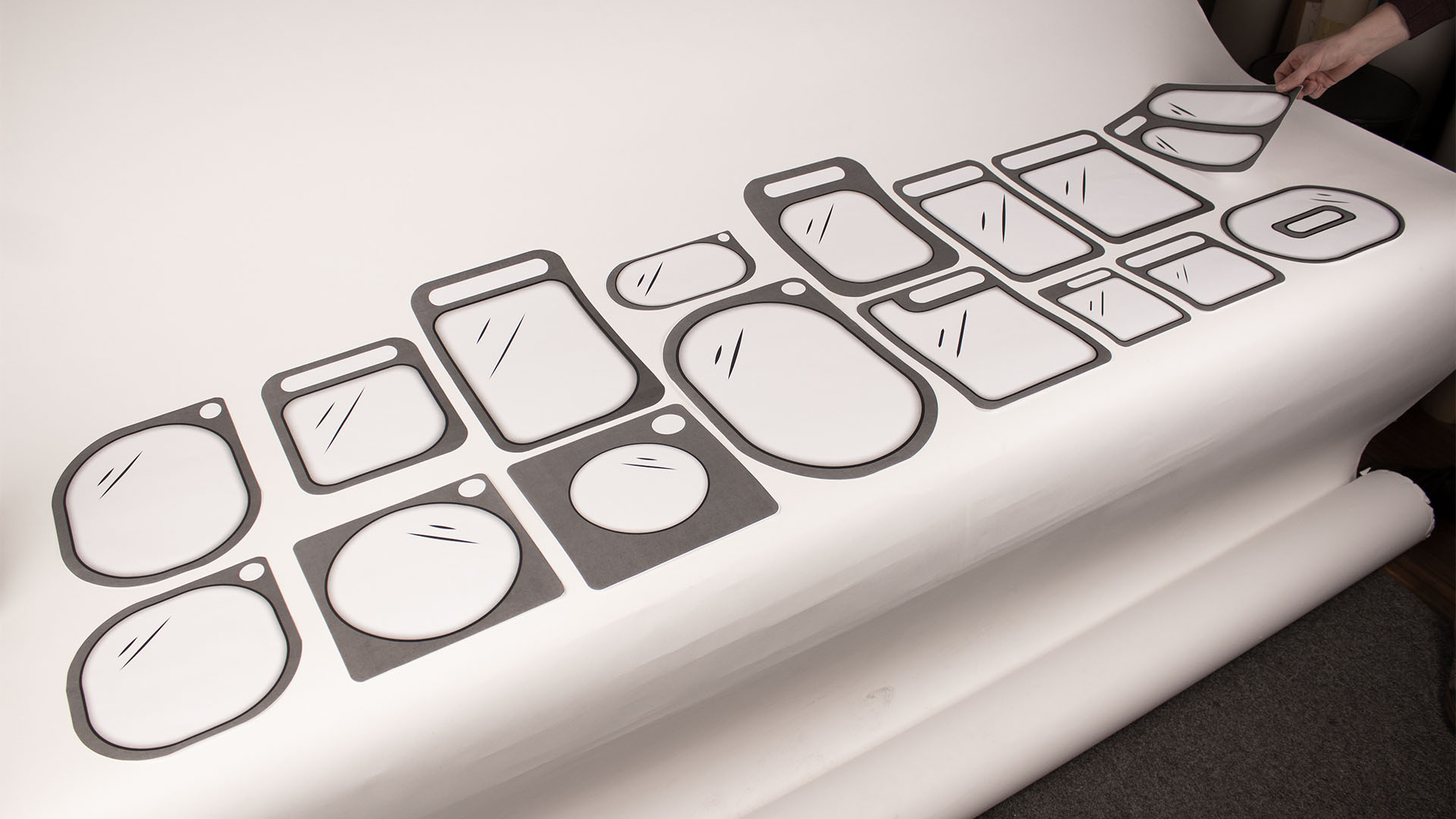

The product consists of two shells,

which in turn consist of a flexible and a rigid component. The

purchase is placed in the packaging and then sealed airtight using negative pressure. In this way, a large variety of quantities of food can be packed. Depending on the service, the retailer, or the customer himself then takes over the loading of the units. This means that delivery and collection services could also make sensible use of

REPAQ.

After transport, the air is allowed to flow back into the packaging by pressing an inserted valve pocket, the product can then be opened. After the food is removed, the packaging loses its purpose and can be returned to the retailer/supplier. There REPAQ is cleaned and then returned to the cycle.

After transport, the air is allowed to flow back into the packaging by pressing an inserted valve pocket, the product can then be opened. After the food is removed, the packaging loses its purpose and can be returned to the retailer/supplier. There REPAQ is cleaned and then returned to the cycle.

TASK _ DEVELOP A SUSTAINABLE PACKAGING CONCEPT

FOR GROCERY STORE APPLICATIONS

︎︎︎

WHY ?

WE NEED TO CHANGE THE USE OF ONE WAY

PACKAGING AND OUR PURCHASING BEHAVIOUR ...

Why always 500g pasta? For logistical reasons, food is predominantly offered in unit sizes. The quantities required by each customer vary greatly. Is individual packaging necessary? In the food supply chain, it is only the last step from the retailer to the customer or consumer that requires division by individual packaging.

Do we shop differently today? A new trend in shopping behavior can be observed especially in cities. The big weekly shop is giving way to smaller and more frequent errands.

And why is the proven bottle deposit system which is already being used successfully in some countries not being transferred to other areas of the food industry? REPAQ should be an attractive, universal, and sustainable option for exactly this purpose.

And why is the proven bottle deposit system which is already being used successfully in some countries not being transferred to other areas of the food industry? REPAQ should be an attractive, universal, and sustainable option for exactly this purpose.

HOW ?

DEVELOPING A NEW ARCHETYPE FOR FOOD SHOPPING...

The product had to be as simple as

possible for cleaning, production, and recycling, but also meet the

requirements of safe packaging. Keywords for the development process included: Sustainability by replacing disposable packaging so only one product instead of many small and individual units. Individuality by adjusting quantities to avoid superfluous packaging and food waste. Universality through different supply scenarios like pickup services, classic shopping, or delivery.

Vacuuming has many uses in food storage and cooking.

A durable, high-quality, and reusable packaging concept could also use this method to seal itself, fix different purchases and keep food fresh. The fixed condition of open and closed also allows a systematic return cycle.

The product consists of two shells,

which in turn consist of a flexible and a rigid component. The

purchase is placed in the packaging and then sealed airtight using negative pressure. In this way, a large variety of quantities of food can be packed. Depending on the service, the retailer, or the customer himself then takes over the loading of the units. This means that delivery and collection services could also make sensible use of

REPAQ.

After transport, the air is allowed to flow back into the packaging by pressing an inserted valve pocket, the product can then be opened. After the food is removed, the packaging loses its purpose and can be returned to the retailer/supplier. There REPAQ is cleaned and then returned to the cycle.

After transport, the air is allowed to flow back into the packaging by pressing an inserted valve pocket, the product can then be opened. After the food is removed, the packaging loses its purpose and can be returned to the retailer/supplier. There REPAQ is cleaned and then returned to the cycle.

FINAL RESULT

Project Titel _ REPAQ | +1 Team member / Marius Greiner

Supervised by Prof. Wolfgang Schabbach | Coburg University of Applied Sciences

Awarded with the IF - Design Talent Award 2020

Special thanks to Wolfgang Rößler for teaching and support.

Supervised by Prof. Wolfgang Schabbach | Coburg University of Applied Sciences

Awarded with the IF - Design Talent Award 2020

Special thanks to Wolfgang Rößler for teaching and support.

Project Titel _ REPAQ | +1 Team member / Marius Greiner | Supervised by Prof. Wolfgang Schabbach |

Coburg University of Applied Sciences

| Awarded with the IF - Design Talent Award 2020

Special thanks to Wolfgang Rößler for teaching and support.

Special thanks to Wolfgang Rößler for teaching and support.